Abstract

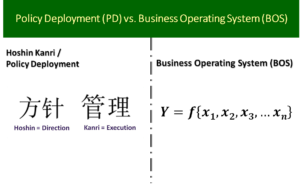

This document compares the practices of ‘Business Operating System’ and ‘Policy Deployment’. Both the practices enable the cascading of business goals of the company down the organisational hierarchy – laterally and vertically. Policy Deployment has its roots in Japan’s Total Quality Management (TQM) movement. Business Operating System evolved as a problem solving methodology in Ford Motor Company, as it started adapting Japan’s TQM practices, in early eighties. Omnex Consultants joined Ford in developing Business Operating System to align the organisational processes and people for achieving business objectives.

Both the practices seek to establish a relationship between strategic business objectives and the performance expected from various functions/processes. While, the Policy Deployment relies on the ‘catch-ball’ process for achieving consensus about the business objectives; a cross functional team under the Business Operating System strives to establish mathematical relationship and then set the targets for business objectives. The two practices have been compared for subtle differences. Proponents of both the practices would claim that their respective practices can accommodate the features of the each other. The document ends with an inference that either of the practices can be used for cascading the business objectives throughout the organisation.

Business Operating System: Definition

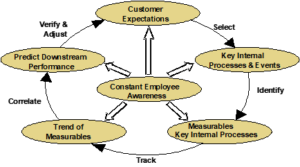

Business Operating System (BOS) is a systematic, disciplined approach that uses standardised tools and practices to manage business and achieve ever-increasing levels of customer satisfaction through continual process improvement.

BOS is an upstream methodology to achieve business objectives. Upstream is defined as the activity which takes place early in a process and has an impact on achievement of specific events to take place later in a process.

History of BOS

The BOS was developed by Ford as ‘Quality Operating System’ (QOS) in 1985. Omnex consultants were involved in the development process. They started propagating the concept as BOS for other clients.

Ford included the deployment of QOS as a necessary element of its Q1-Award for its suppliers.

Since, the concept evolved as a quality improvement tool, its application in manufacturing was more towards quality improvement.

BOS: The concept

The BOS attempts to build a mathematical relationship between the business objective (Y) and key internal business processes (X1, X2, . . ., Xn). Each of the stakeholder objectives is taken up and its successful completion or attainment is defined in terms of outcomes of key internal processes and events. These outcomes can also be called as ‘Result Measurables’ (Y).

The outcome (Y) could be an output of one or more than one processes, wherein the process could act in mutually exclusive manner or interact with each other. Each of these processes could be influenced by process variables (X).

The BOS seeks to identify those process variables (also called as process measurable’s) and track them for studying their impact on ‘Result Measurable’.

The BOS then seeks to bring the contributing processes to such a level that together the business objective Y is achieved. In other words, it seeks to establish a mathematical equation:![]()

If any process variable is not at a level to enable the attainment of the business objective, quality engineering tools n techniques like Lean Methodology, Six Sigma, etc. could be deployed in form of projects to reduce the gap between actual vs. desired value of Y.

Once, the mathematical relationship is established, the BOS advocates only the measurement of process variables and then predict the result Y. This upstream prediction helps as an early warning system and facilitates timely corrective action.

BOS fosters employee involvement, as the implementation is supposed to be done by a cross functional team and employee group activities (e.g., quality circles) are encouraged to participate in the improvement projects.

The BOS implementation could be summarised in following steps:

- Step 1: Organise leadership team

- Step 2: Define Mission, Vision and Values

- Step 3: Identify customer expectations and result measurable’s

- Step 4: Establish Strategic objectives

- Step 5: Identify key processes and measurable’s

- Step 6: Formulate data management plans

- Step 7: Selecting improvement projects.

Policy Deployment: Definition

Policy Deployment is a step-by-step planning, implementation, and review process for managed change. Specifically, it is a systems approach to management of change in critical business processes. A system, in this sense, is a set of coordinated processes that accomplish the core objectives of the business.

Policy Deployment refers to methods used to ensure that everyone in the organization is working effectively towards the same end. Efficient deployment of policies requires not only that the policies be communicated without ambiguity, but also that the policies be workable and understandable by those who are to carry them out.

Policy Deployment: History

The incorporation of the quality management principles (e.g. Deming’s fourteen principles) for the management of the industrial organization yielded a system known, in Japan, as ‘hoshin kanri’. The term ‘kanri’ is Japanese for ‘control’ and as no word exists in the Japanese language for management it also means ‘management’. The term ‘hoshin’ is made of two Chinese characters: ‘ho’ meaning a method or form and ‘shin’ meaning a ‘shining needle’. Together, the term ‘hoshin’ is an analogy to the needle of a navigational compass. Putting the two together we get ‘navigational management’ and this is the essence of ‘policy deployment’.

It was first used in 1965 by Komatsu. In some companies, instead of ‘hoshin kanri’ the method is called ‘policy deployment’. Apart from its acceptance by Japanese organizations; many organizations in the western world have also adopted policy deployment. Some of the notable organizations are Hewlett Packard, Xerox Corporation, Procter & Gamble, and Ford Motor Company.

Policy Deployment: The concept

At the core of the Policy Deployment, lays the Deming’s ‘Continuous Improvement Cycle’ or also known as Plan-Do-Check-Act (P-D-C-A) cycle. In policy deployment, the cycle is used in a different manner as: Check-Act-Plan-Do.

Apart from the PDCA loop, the Policy Deployment process relies on:

- extensive organization wide communication of business plans,

- cross-functional working,

- getting a ‘buy-in’ of the business objectives from sub-ordinate hierarchies through the ‘catch-ball’ practice,

- Cascading the objective to tasks which are either standardized or could be managed using the principles of ‘Daily Work Management’.

- Assessment and review of the ‘policy deployment’ process itself leading to continuous improvement and standardization.

Hoshin Model

The method of policy deployment could be explained in following steps:

Check

Step 1 – After evolving a mission and a long-term strategy for its attainment; the senior management reviews the business results against its future goals and identifies opportunities for improvement. Improvement is sought in business performance against each stake-holder expectations.

Act

Step 2 – Opportunities for improvements are selected and converted in to key improvement challenges with break-through targets for quality, cost and delivery performance. These targets are communicated/presented to the middle management.

Step 3 – the middle managers engage in a study to understand the business requirements and generic adjustments to the business that could be made. This activity usually involves a process known as ‘catch ball’ and involves the tossing of issues between a management team to explore and highlight the ramifications of any chosen course of action or improvement program. Those issues that can be immediately agreed by the middle management team are sent back to the senior management. The senior management team therefore determines which course of action is most suitable to the organization and engages in the catch ball process with the middle managers again. This second loop is important as unresolved issues need authorization and would imply that a department in the business may be sub-optimised in order to improve the entire business.

Plan

Step 4 – In addition to the catch ball process, the middle managers are actively engaged in finding out ‘How’ to solve the challenges set.

Step 5 – Once the projects are selected then another round of promotion and catch ball is undertaken by the middle managers with the teams in the factory. This is a means of promoting awareness and clarifying issues in more detail. At this level, the ‘accepted’ projects and on-going improvement targets are deployed to the team leader. In addition, project time scales are determined and individuals assigned to projects. The measurement systems are adjusted accordingly (with the annual departmental targets declared).

Do

Step 6 – the teams work on the improvement projects as per the timeline decided. The tasks that have standards are tracked by control plans.

Step 7 – the progress of improvement actions is monitored at operational level are monitored more frequently. The senior management monitors the progress of the objectives and also the entire process for any corrective action.

Comparison

The deployments of BOS are limited to Ford’s operations, suppliers and clients of Omnex consultants. On the other hand the practice of Policy Deployment has wide acceptance globally on account of western industry’s endeavour to bridge the gap in business excellence when compared with Japan. The comparison of the two practices should be taken in cognisance of the above limitations.

| Business Operating System | Policy Deployment |

| Origin | |

|

|

| Business Objectives | |

|

|

| Model | |

|

|

| Target vs. Actuals variance | |

|

|

| Emphasis | |

|

|

Inference & Recommendation

Both the BOS and Policy Deployment are means for communicating and cascading of strategy. Both practices seek to foster cross-functional process based working and employee involvement. After discussion with Omnex, we understand that BOS was co-developed by Ford, to adapt the TQM practice of ‘Hoshin Kanri’.

It is hence recommended that either of the practices could be used based on availability of knowledge resource.

Reference

- ‘Quality Operating System (QOS)’ – Awareness Training – Ford Motor Company.

- ‘Policy Deployment’ – by Myron Tribus

- ‘Business Process Management: A boundryless approach to modern competitiveness’ – by Mohamed Zairi, Business Process Management Journal, Vol. 3 No.1, 1997, pp. 64-80.

- ‘Policy deployment: An examination of the theory’ – by R.G. Lee and B.G. Dale, International Journal of Quality & Reliability Management, Vol. 15 No. 5, 1998, pp. 520-540.

- ‘Policy Deployment: Taking Strategy into Action’ – Deloitte and Touche Senior Executive Series of Briefing Papers.

- ‘Workshop on Strategic Business Planning’ – Confederation of Indian Industry, Course Material.